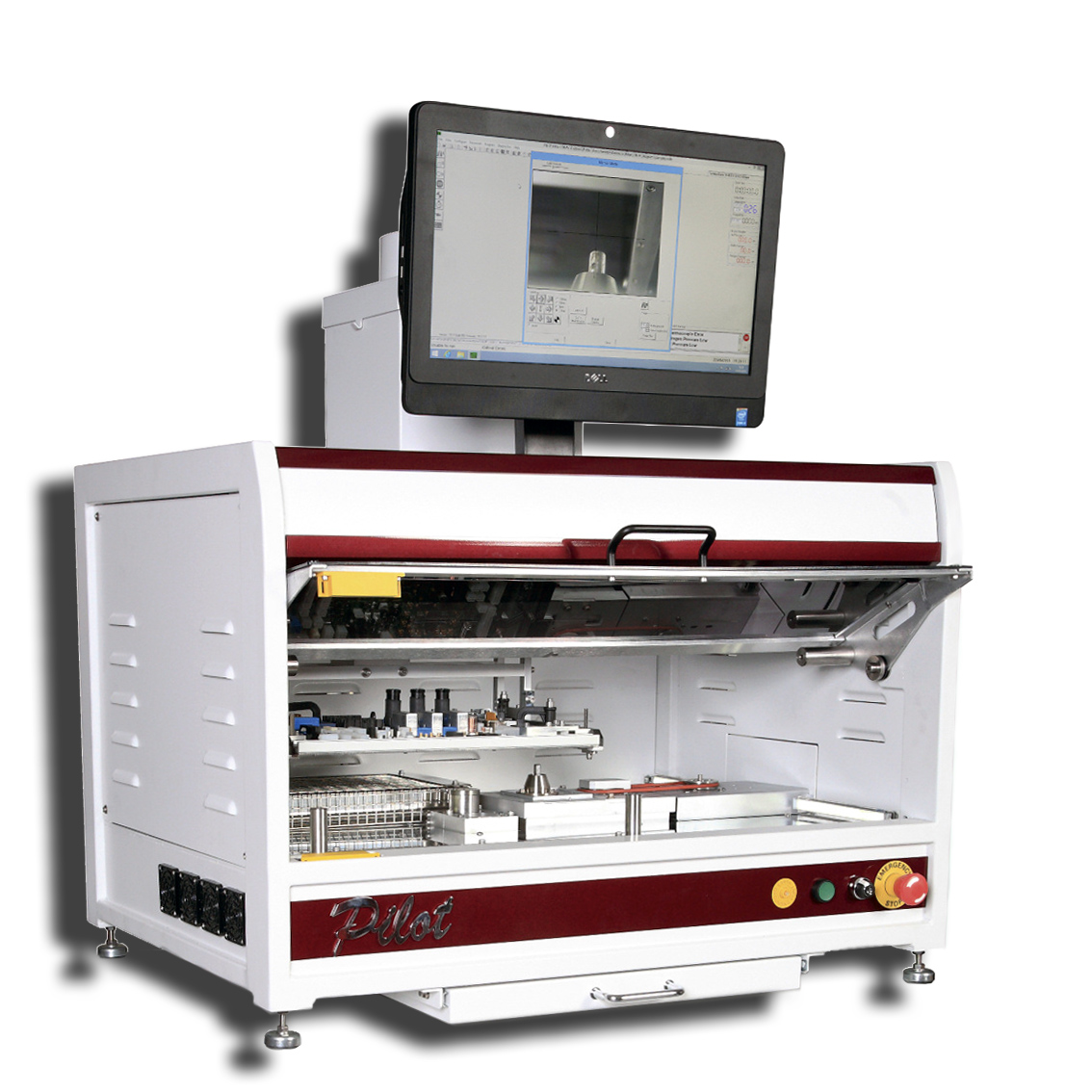

Technical spécification

| Height: | With monitor 1025mm / 40” With cowling 726mm / 29” - without 670mm / 26” |

| Width : | With flux bottles 1090mm / 43” - without 915mm / 36” with solder bath out 1380mm / 54” |

| Depth : | 700mm / 28” to 963mm / 38” with keypad tray out |

| Board size : | 330mm x 250mm / 13" x 10" |

| Edge clearance : | Above / below 3mm |

| Height clearance : | Above / below 40mm nominal, 55mm Max |

| Solder : | All commonly used solder types - including lead-free |

| Solder pot capacity : | 6kg / 13lb |

| Applicators : | - AP style - 2.5mm to 16mm Ø. - Extended AP style - 2.55mm to 20mm Ø - NB - Micro nozzle - 1.5mm to 2.5mm Ø - Jet-Tip style - 6mm to 40mm Ø. - Special dedicated nozzles available upon request |

| Flux : | Low maintenance Drop-Jet system. Low solids (below 8%), no clean flux, pressurised and inerted system, optional water-soluble system available |

| X, Y & Z Axis resolution : | 0,1mm |

| Repeatability : | +/- 0,05mm |

| Nitrogen usage : | 30 liters gas/min. |

| Pression : | 5 bar |

| Nitrogen purity : | 99,99% Ou supérieur |

| Power supplies : | Single phase + PE - 208V / 250V - 50/60Hz |

| Power : | 4kVA including bottom-side IR preheat |

| Transport : | Hand load |

| Tooling : | Integral adjustable board guides, includesfinger extensions and board clamps |

| Programming : | Fonctionne sous Windows : - PillarCOMM ‘Point & Click’ - |

Standard features

• Integral PC and machine mounted TFT monitor

• Inerted nitrogen system

• Drop-Jet fluxer

• Two AP style solder nozzle tips

• Internal fume extraction

• Colour programming camera

• Two universally adjustable tooling carrier

• PillarCOMM LITE

• Windows® based ‘Point & Click’ interface

• Lead-free compatible

• Day-to-day service kit

System options

• Fume filtration system

• Manual fiducial correction

• Micro nozzle assembly

• PillarPAD offline programming system

• Multiple level password protection

• Bottom-side preheater

• PillarGEN 30 nitrogen generator and machine stand